Our Products

Sarkar Enterprises is an ISO 9001 : 2008 certified company also having all mandadory certifications like, Factory Act License, Fire NOC, MSME registration. We are also in Green vendor category from " Maruti Suzuki India pvt. Ltd."

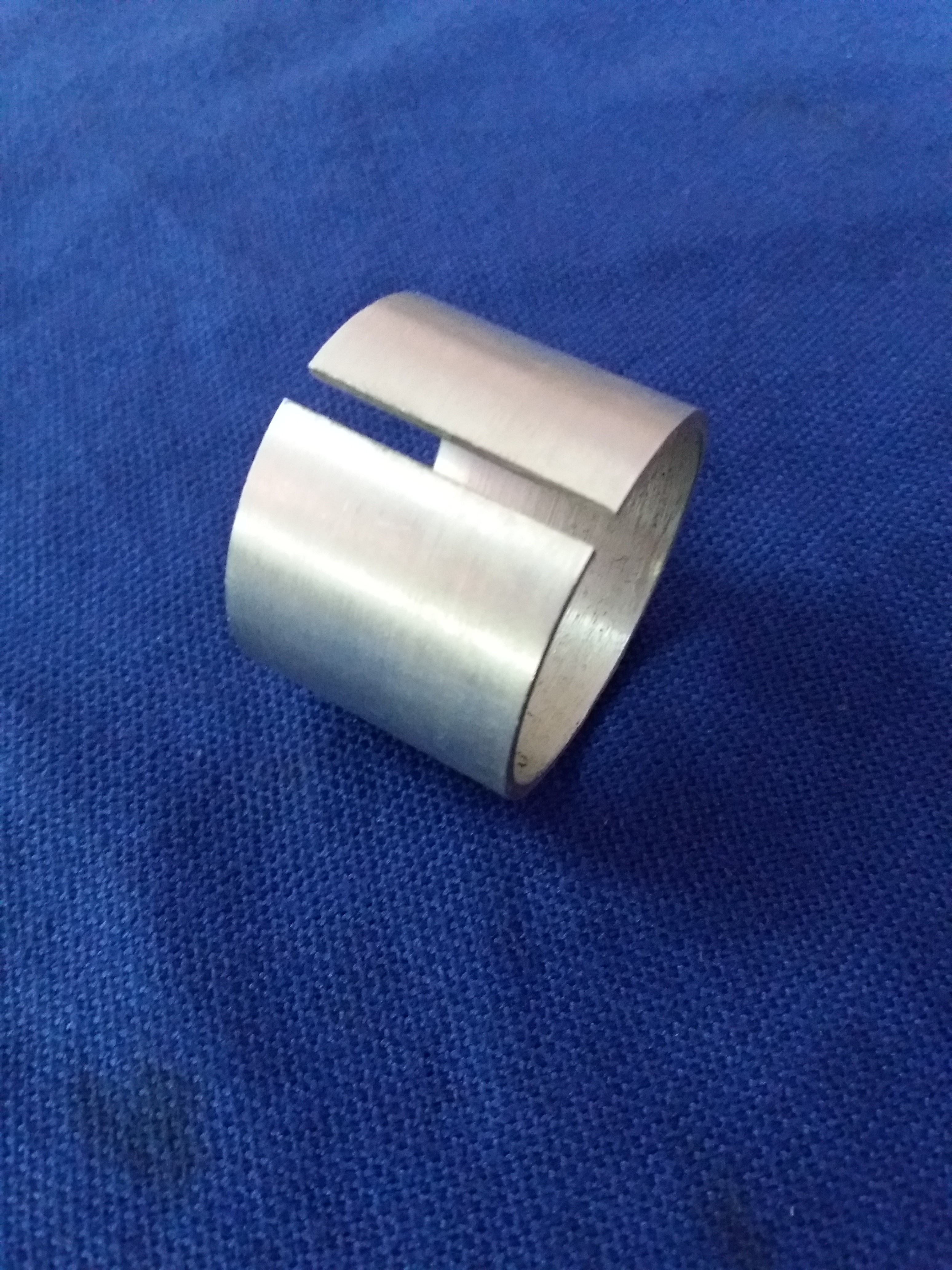

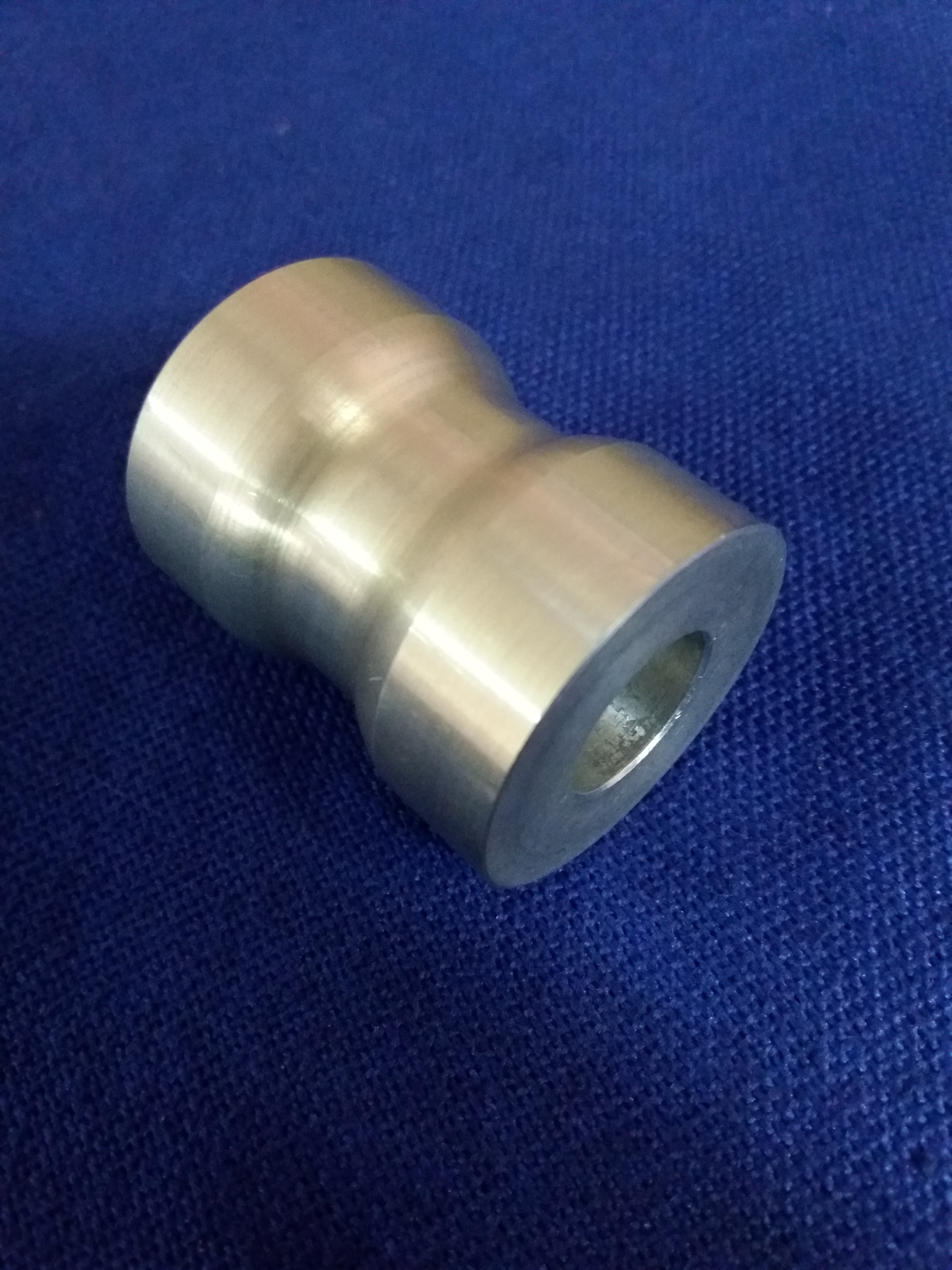

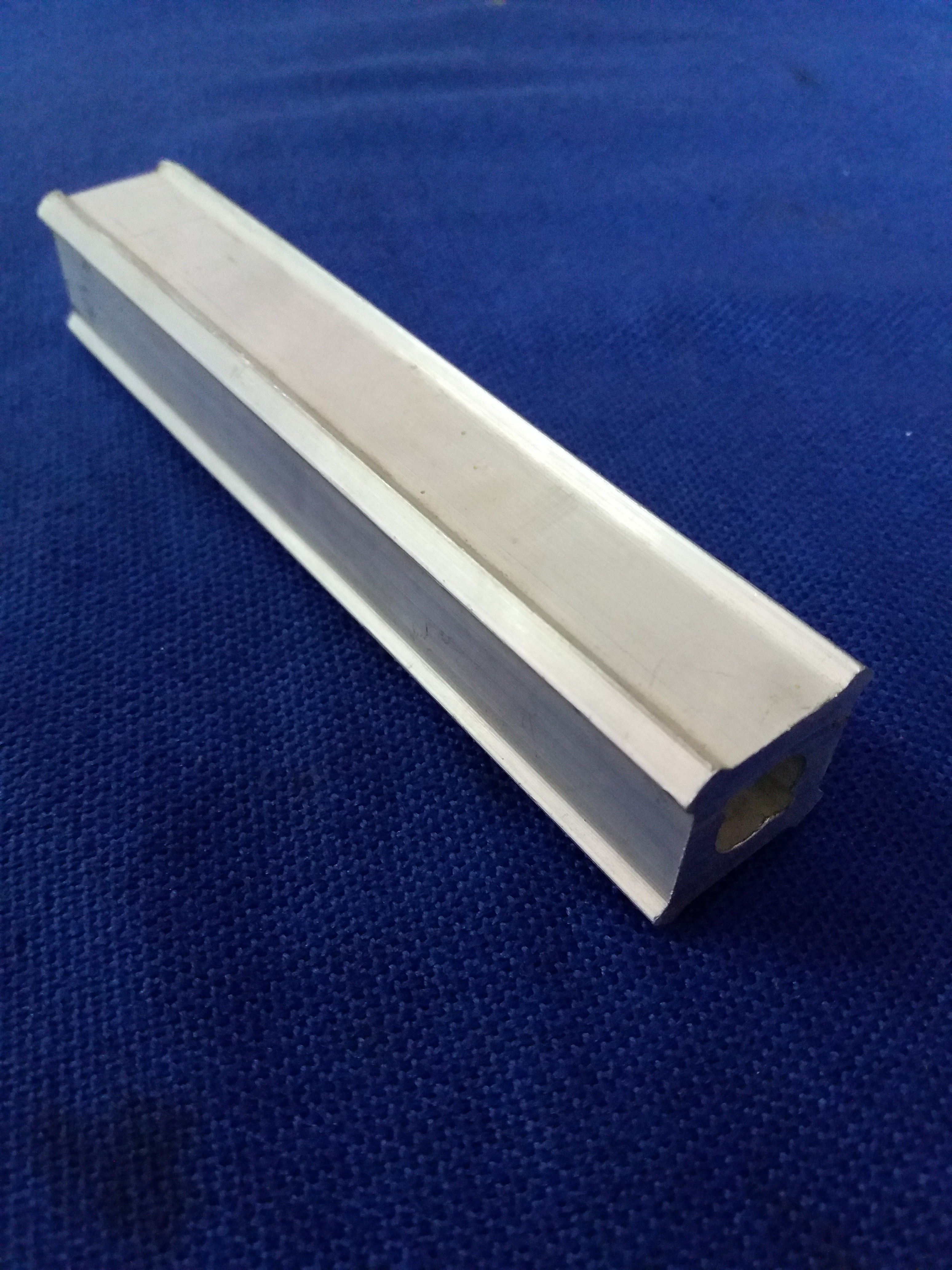

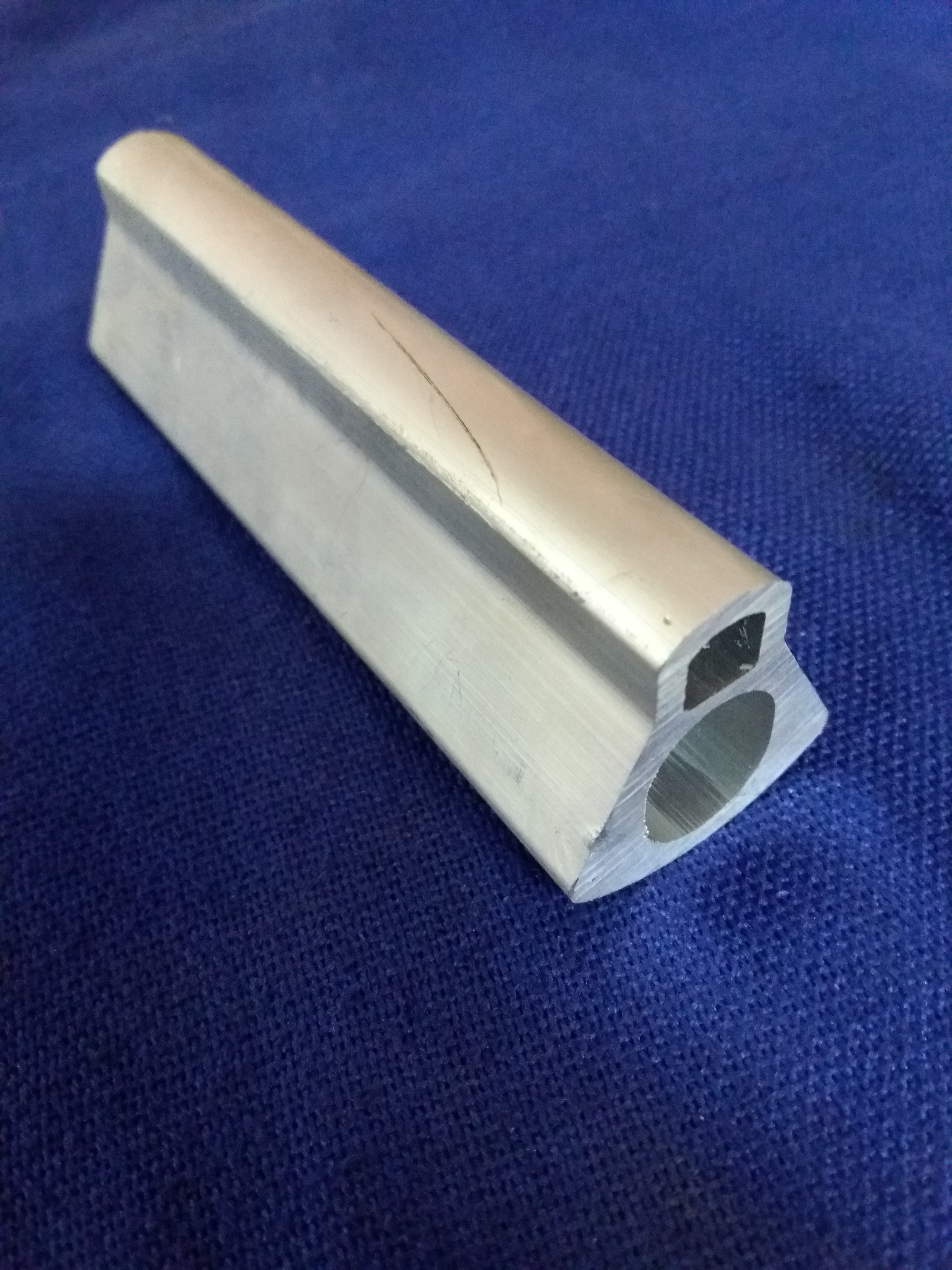

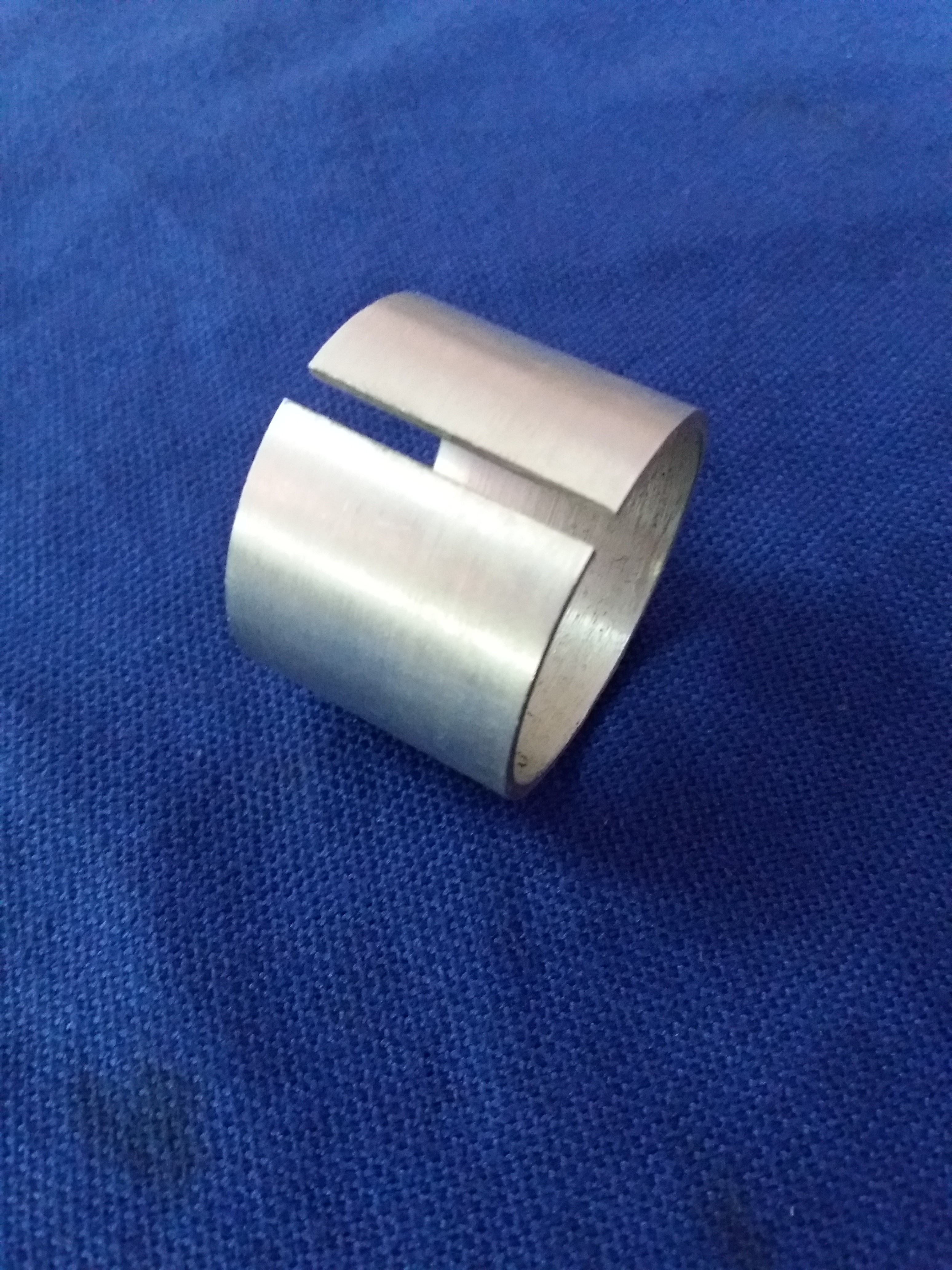

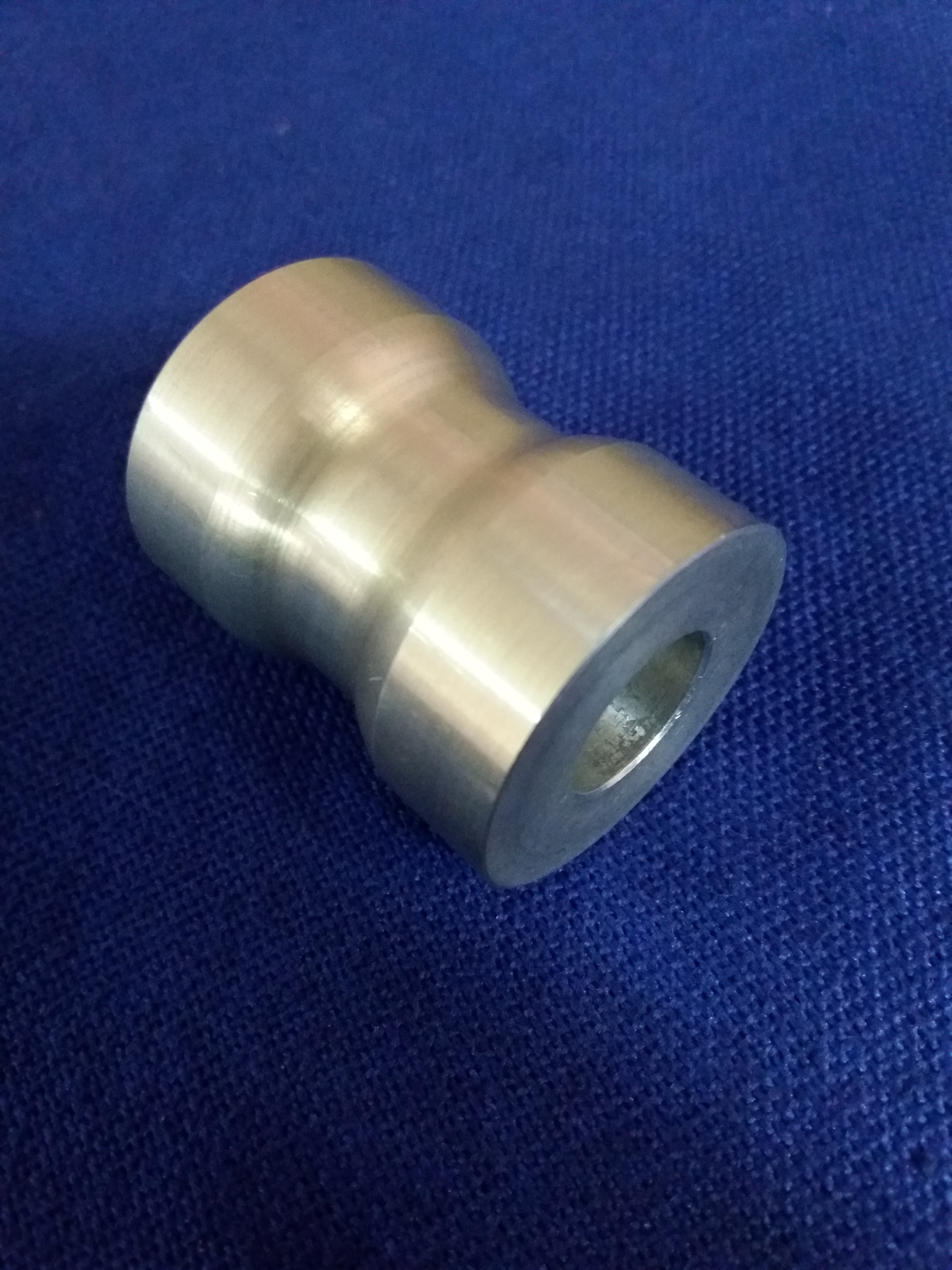

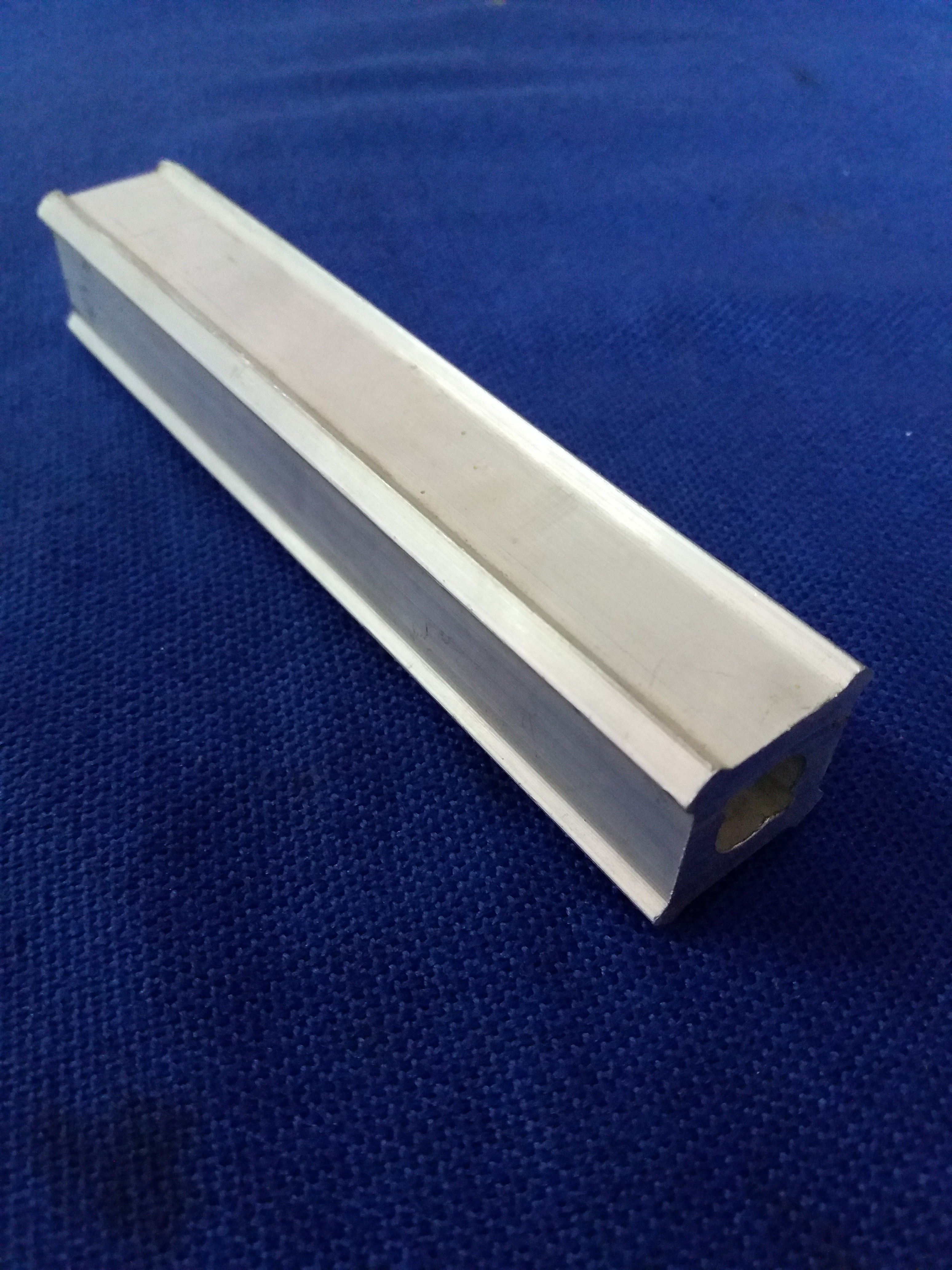

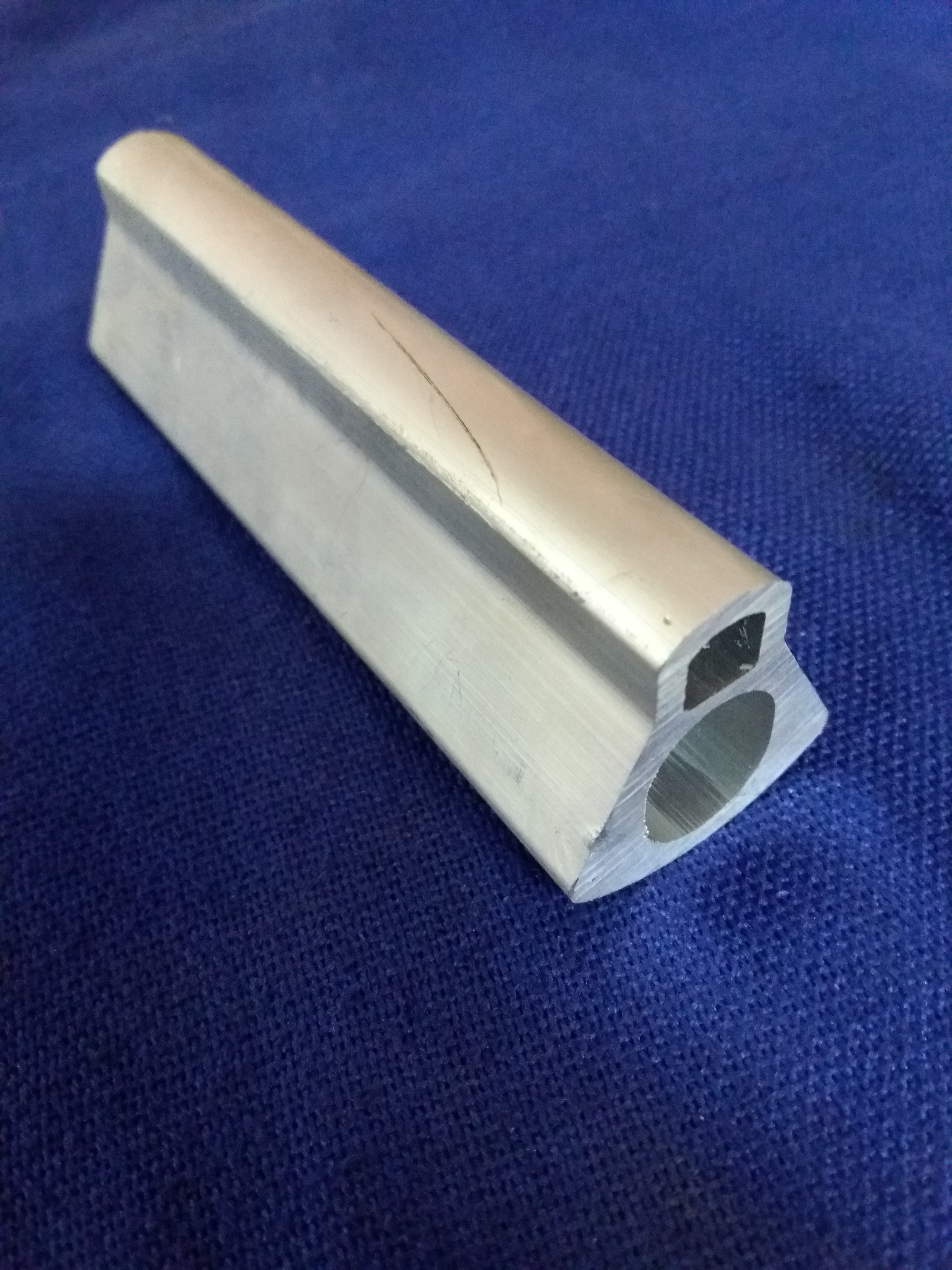

We are manufacturer of Automobile Components, Turned components, Pipe/Tube cutting (steel & aluminium) 5mm to 100 mm Dia, Aluminium Extrusions & section Cutting, Threading, Milling, Drilling, etc. we do both sale and job work components. We have all dia range Automatic TRAUB machines (Germany make), CNC machine, Tube cutting machine, Centerless grinder, Mechanical press, Drill machine, Milling machine, threading machine etc.

Sarkar Enterprises was established in the year 1980 at Plot No. 7 & 10, Block No. 213, Daulatabad Industrial Area, Gurugram, Haryana (India) with the intention of manufacturing of automobile turned components and automobile components & Tube/Pipe cutting upto 110mm diameter.

We are observing 3 tier quality control System -

(1) Pre Manufacturing

(2) Manufacturing

(3) Post Manufacturing

(1) Pre-manufacturing :- Pre manufacturing Quality control is being

observed right from the procurement of the material only through

reputed manufacturers like USHA, MUKAND,T.I. Ltd., Atlas Pet Plas,

Avon Tubes, Automan, (B S P)arcaded distributors like Gopal sons

etc. ensuring each time the material is brought for proper

specifications.

(2) Manufacturing :- The manufacturing is being done on high

precision Automatic Machines constant check is being maintained

during manufacturing process by checking a component against

specifications for any deviation through micro Meters, dial Vernier,

Calipers, dial Indicators, Digital Vernier, High Gauge, Pappy Dial,

Thread, Flange, length, Outer, Dial, Inner Dia,Gauges, Which are

callibered periodically.

(3) Post Manufacturing :- Each lot is verified by 100% inspection

with different types of gauges also visually verified 100% and

packing is done as per packing standard provided by customer.